Difference between revisions of "HDX Team 3 - Smart Grocery"

imported>Aldosinaga |

imported>Aldosinaga |

||

| Line 121: | Line 121: | ||

Figure 4 FoodHall Store | Figure 4 FoodHall Store | ||

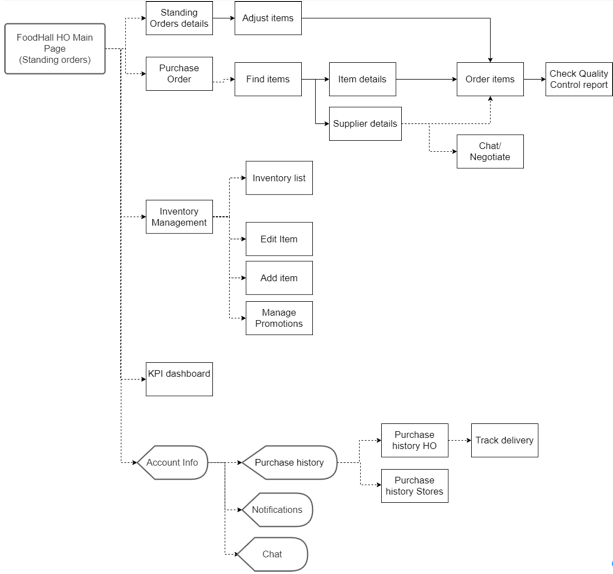

The business process of FoodHall Head Office is presented in Figure 5. The FoodHall HO is responsible in placing the Purchase Order of the perishable produce from supplier. There are two types of Orders from FoodHall HO: Standing Order and Purchase Order. Standing Order is for regular and repeated order, whereas the Purchase Order is to proceed the FoodHall Stores requisitions. The received goods will go directly to FoodHall Store or Distribution Center. The FoodHall HO can also manage promotions of the items. All the promotions are decided by FoodHall HO to be applied to all FoodHall Store. This promotion is connected by the POS system of FoodHall. All the transaction data will also be connected to the FoodHall SAP system, by applying back-end synchronization function. The FoodHall HO must be able to monitor the performance of all involved parties: Foodhall Store, Supplier, and Distribution Center. A KPI Dashboard provides all the information needed for monitoring process. This Dashboard system will apply a machine learning process to explore statistical and historical information from the SAP. The FoodHall HO can obtain real time performance of Foodhall Store, Supplier, and Distribution Center and the trends of the supply and demand of perishable | The business process of FoodHall Head Office is presented in Figure 5. The FoodHall HO is responsible in placing the Purchase Order of the perishable produce from supplier. There are two types of Orders from FoodHall HO: Standing Order and Purchase Order. Standing Order is for regular and repeated order, whereas the Purchase Order is to proceed the FoodHall Stores requisitions. Store Number is used for internal requisition order to HO. The received goods will go directly to FoodHall Store or Distribution Center. The FoodHall HO can also manage promotions of the items. All the promotions are decided by FoodHall HO to be applied to all FoodHall Store. This promotion is connected by the POS system of FoodHall. All the transaction data will also be connected to the FoodHall SAP system, by applying back-end synchronization function. The FoodHall HO must be able to monitor the performance of all involved parties: Foodhall Store, Supplier, and Distribution Center. A KPI Dashboard provides all the information needed for monitoring process. This Dashboard system will apply a machine learning process to explore statistical and historical information from the SAP. The FoodHall HO can obtain real time performance of Foodhall Store, Supplier, and Distribution Center and the trends of the supply and demand of perishable produce. This information will also support the decision-making process. FoodHall HO manages the inventory and their account information: purchase history, requisition history, and track delivery. | ||

[[File:Figure 2 5 FoodHall Head Office.png]] | [[File:Figure 2 5 FoodHall Head Office.png]] | ||

Revision as of 11:48, 18 August 2021

Project Background

The Foodhall is one of PT. Mitra Adiperkasa Tbk business segments. The business is grocery retail with two types of premium supermarket concepts: The Foodhall, a large format supermarket and Daily Foodhall, a smaller format supermarket located mostly in residential areas. Our project team has been tasked to examine Foodhall’s current retail strategy and propose viable solutions for The Foodhall.

The COVID-19 pandemic has posed numerous challenges to businesses especially those that are operating as brick and mortar stores. It is just one of the factors listed by our stakeholders as motivation for a rethink on retail strategy. Another consideration is how Foodhall can structure an end to end solution for its supply chain that would reduce wastage, reduce middlemen, and enhance the experience for its suppliers and consumers by offering fresh foods at the best possible price and quality.

The team got down to our challenge by first looking at the system, namely the supply chain. We used the iceberg model to identify patterns and trends as well as the mental models, we also looked at our system problem statement to define our why of the challenge as well as the what and how. We came up with the stakeholders most relevant to the challenge at hand and their importance relative to Foodhall. Descriptive goals were then drawn up and metrics for measurement to keep us aligned to success led to the next steps which was to develop an app that would track purchase and supply data and democratise this across the entire supply chain to achieve better provision of fresh foods to the end user and reduce waste. These various steps are highlighted in the next sections.

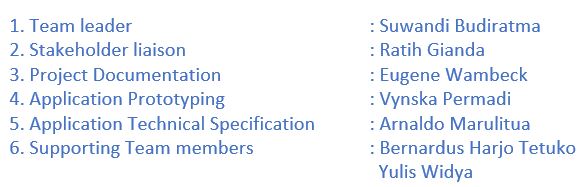

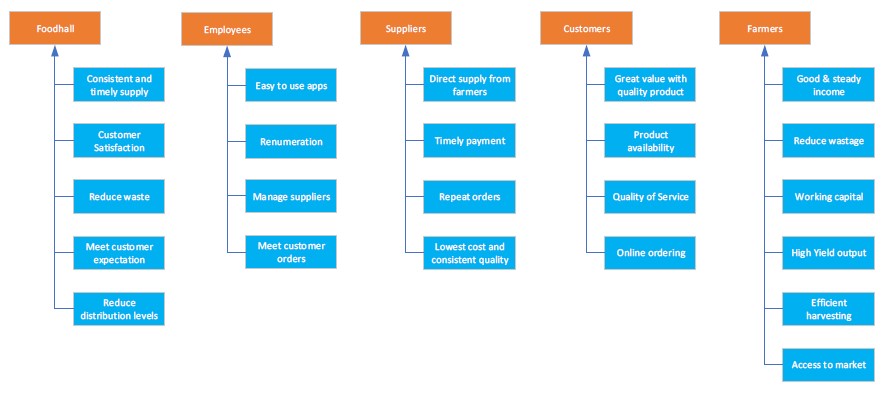

Team Members

Project Milestones

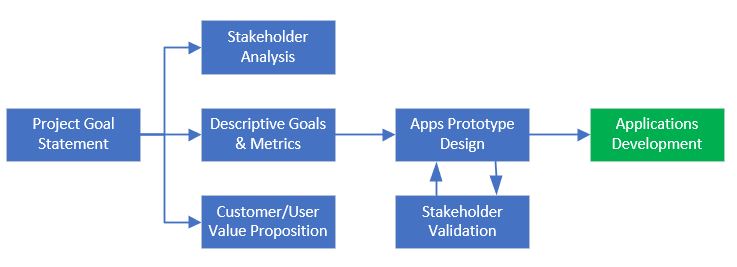

Iceberg Model (Systems View)

The figure 1 below shows our iceberg model for our complex system from a consumer standpoint. From the business standpoint, after speaking with our stakeholder Foodhall, we understand that there is sometimes a separation in ordering patterns at the store level as opposed to head office as well as a reliance on manual modes or ordering. Hence, it would be of value to create a unified end to end solution that would be able to handle both store level and head office level ordering and supply management. In our redesign, some stakeholders such as the middlemen suppliers might be displaced especially if they cannot consistently deliver value to the produce supply chain, or integrate into the idea of information exchange and systems integration but that this exercise is worth the effort as it would bring in more predictable outcomes such as a more responsive supply chain.

Figure 1 : Iceberg Diagram

Goal Statement

Our team examined the goal of the challenge and how to deliver value to the project that is representative of real success. The ‘To, By and Using’ goal statement we established is:

- To : Reduce wastage of perishable produce, get low price for customer while improving farmers’ welfare. Reduce wastage of perishable produce, get low price for customer while improving farmers’ welfare

- By : Shortening the produce supply chain through predictive orders

- Using : An on-demand digital ordering system

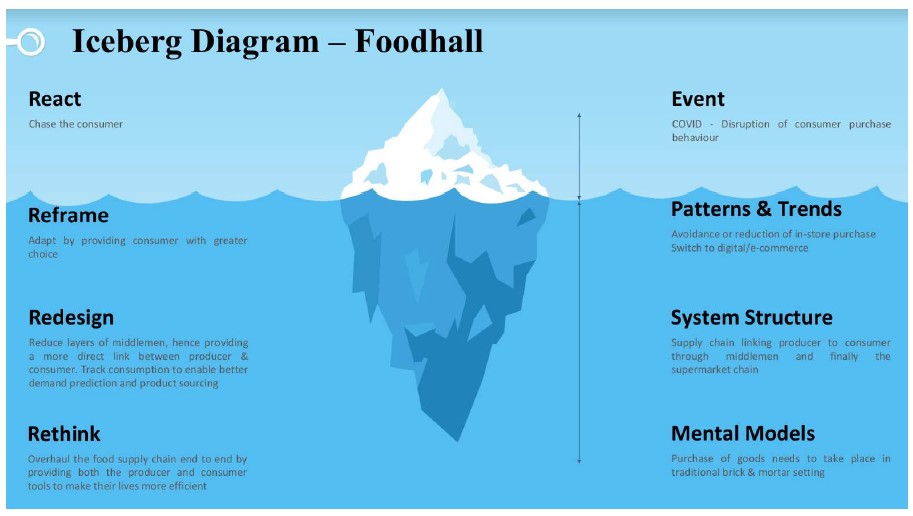

Stakeholders Analysis

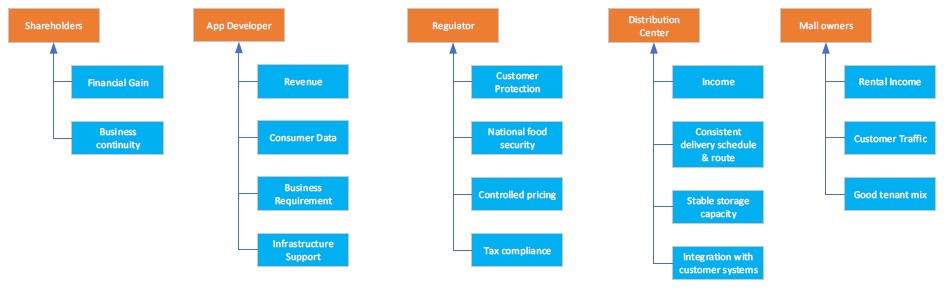

For an end to end solution, we identified at least 10 stakeholders. These stakeholders are relevant to the Foodhall challenge now and into the future. Figure 2 illustrates these stakeholders and their respective needs.

Figure 2 : Stakeholders Analysis

The stakeholders can be further defined as those who might be directly involved in the supply chain, for instance, the Farmers, Suppliers, the Distribution Centre, Foodhall itself as challenge project owner as well as those who are potentially indirectly connected such as the App Developer, Regulator, Shareholders and Mall Owners and finally both directly and indirectly, namely the Employees of Foodhall since they might be based in back office (head office) and have functions of pushing down supplies to the various store locations or front end staff who might need to make or receive stock replenishments.

Stakeholders Descriptive Goals and Metrics

We identified 14 goals for the project. 7 of these were initially deemed critical to the challenge project. This is illustrated by Figure 3. The goals in Figure 3 are not listed in sequential order. However after speaking with the stakeholder Foodhall, we now understand that a separate system is already in the works for a consumer app.

This led the team to reexamine our ‘why’ of the project. We scaled down the scope of the project to only focus on the supply side. Hence the team worked on the descriptive goals that are essential to delivering an optimized supply chain that would allow for data flows between the farmers, suppliers, distribution center and Foodhall. With an increased information exchange and demand aggregation, more visibility is afforded through the entire system structure providing assurances to the farmers and suppliers as well as to Foodhall and helps to reduce wastage by only catering for demand generated by the end customer. In this way, our project is quite literally Happy Digital X as we are addressing the financial well being of the farmers and suppliers through a more predictable order which should make them happier in the longer term whilst tying up the ecosystem through a digital solution.

In our revision, goals 3, 7, 8, 1 and 2 are critical in ensuring an efficient end to end supply chain.

Figure 3 : Descriptive Goals

Pairwise Interactions

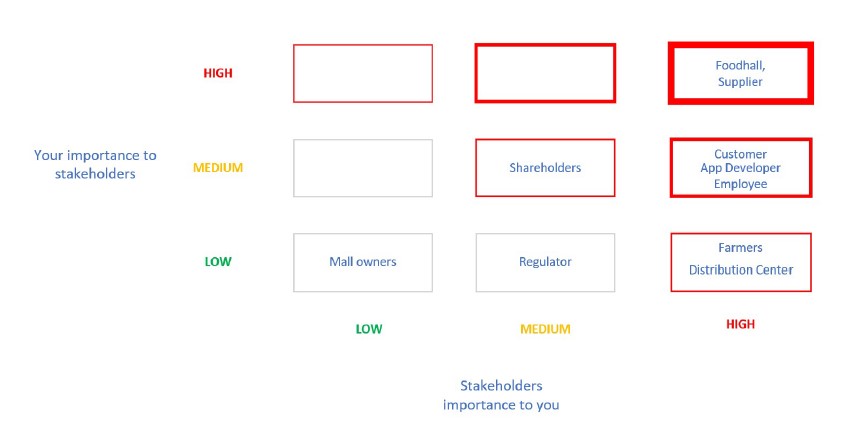

From these ten stakeholders, we did a pairwise interaction based on a 3 by 3 grid. Figure 4 illustrates this.

Figure 4 : 3x3 matrix

The Foodhall and Suppliers are of highest importance to the project. Foodhall, for obvious reasons since they hold the consumption data, trends and patterns as well as the business requirements. The supplier because they are a cog in the system where they hold valuable intermediary data and represent the bridge between the farmers and the distribution centre. Of medium importance is the customer as they represent the demand side and help the project generate revenue from their orders. The app developers are of similar importance as they will be integrating all of the business requirements into an enterprise solution (SAAS) that would handle orders and order tracking for stakeholders such as the Foodhall, farmer, supplier, distribution centre. Finally employees came in at medium, as their buy-in and familiarity with any eventual system is critical for the success of implementation.

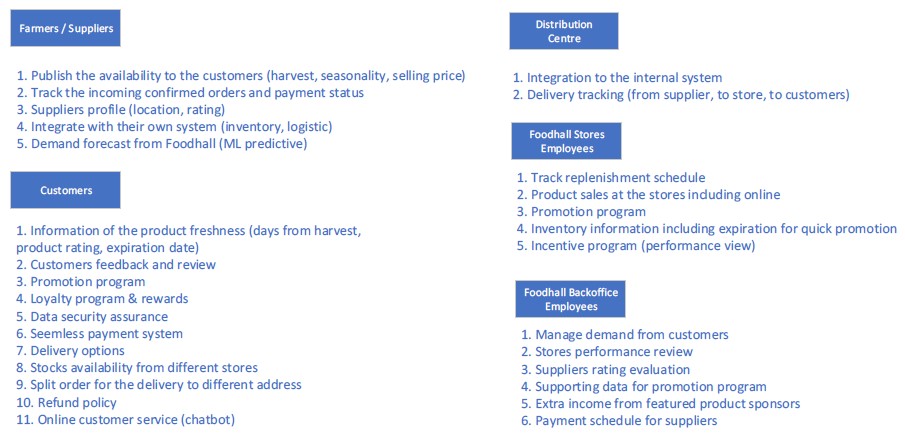

Value Propositions

Our team defined the value that a responsive supply chain would bring to our most important stakeholders. For farmers and suppliers, it would mean an opportunity to share harvest details and produce availability to Foodhall. An integrated system would also give visibility to the farmers and suppliers on incoming orders and payments to increase trust in the system.

Figure 5 maps the value proposition or benefits to each of the five stakeholders. However, as mentioned earlier, Foodhall is developing a separate consumer app, so our challenge project will focus on the four stakeholders groups: farmers & suppliers, distribution center and Foodhall.

Figure 5: Benefits of an end-to-end digital supply chain system

Logical Framework

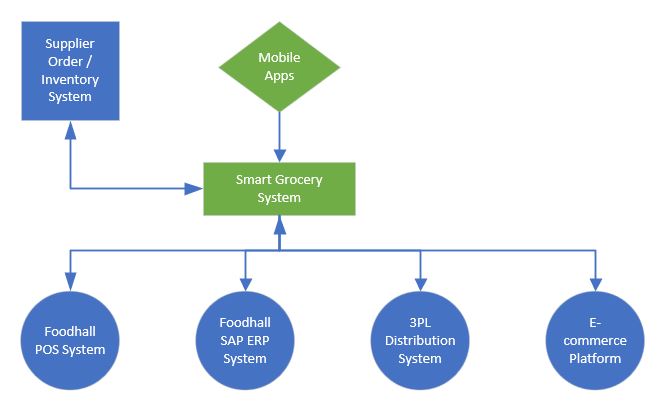

Systems Integration

Application Mockup

The team prepared mockups for various use case scenarios. These include the app interface/wireframe for farmers and suppliers, distribution centre as well as Foodhall Stores and Foodhall Head Office. We further refined this mockup after having a session on 4 August with our Foodhall stakeholder. Through this session, we received valuable feedback on which aspects were important that the app could add value to the end users or facilitate decisions on product requisition. For instance, at the farmer, supplier interface, service level would be important to have. Service level is defined as the ability of the farmer/supplier to fulfil orders quantity. Our stakeholder also shared with us an example of how fruit quality is usually described or quantified: BRIX (sweetness level) and acidity (flavour).

In addition, data such as size of fruit could be added to allow the end user to indicate the distinctiveness of their produce. At the store level, the interface can be further simplified. This means taking away information such as harvest information. The comments we received was that the value of our system does indeed enhance the transparency or visibility of the supply chain. The interface was also viewed as intuitive so the appraisal was that the adoption rate would be high.

Another useful feedback is that with the machine learning function and better analytics, a sweet spot to push higher sales and less wastage is the ideal situation for Foodhall. The other aspect of the system is also knowledge management as data is built.

Technical Documentation

Application Overview

Purpose

In order to fulfill the stated goal statement, an application will be developed. The developed application will help manage supply and demand. The scope of application is focused on perishable produce such as vegetables, fruit, and fresh milk, etc. By automating the supply and demand process, the application system is expected to reduce waste due to imbalance in supply and demand. The system is also expected to reduce the role of middlemen, where FoodHall will be able to communicate directly with suppliers through this application. This project will provide a prototype of the application.

Target System

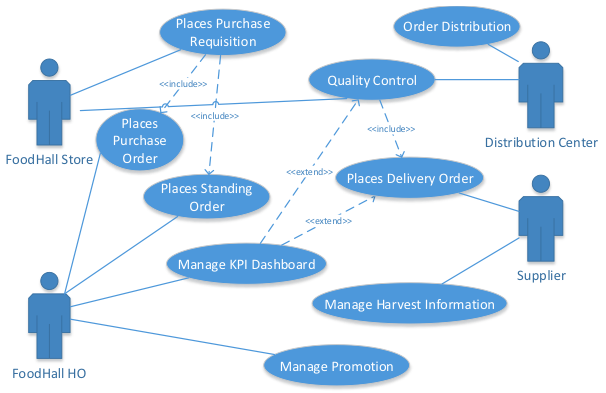

The use case diagram for the target system is presented in Figure 1. There are four main actors. They are FoodHall Store, FoodHall Head Office, Supplier and Distribution Center. Also, there are nine use cases implemented in the system. They are Places Purchase Requisition, Purchase Order, Places Delivery Order, Quality Control, Order Distribution, Manage Standing Order, Manage Harvest Information, Manage KPI Dashboard, and Manage Promotion.

Figure 1 Use Case Diagram

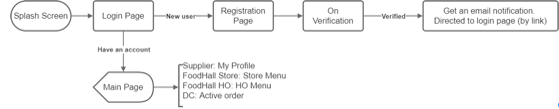

Form that Use Case Diagram, we anaylize the system by defining the detailed business process for each actor. Figure 2 depicts the business process for user registration and authentication.

Figure 2 Registration and Authentication

To access the application, users need to register. The registered users have their specific roles, and therefore they can access features in the application accordingly.

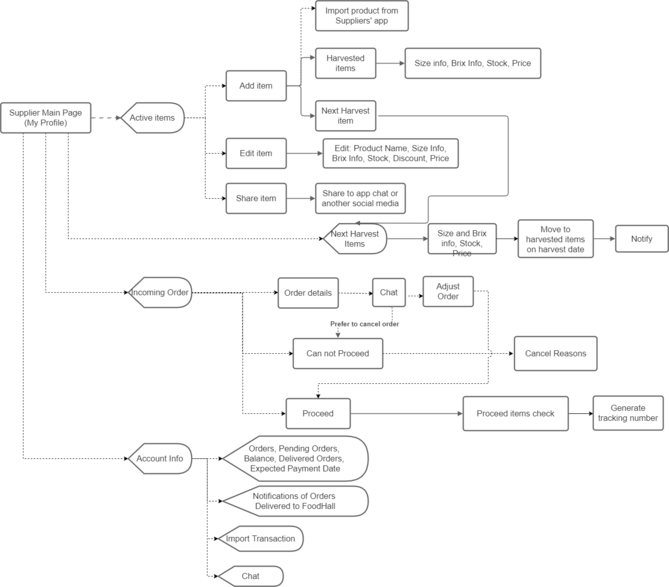

Figure 3 Supplier

Figure 3 presents the business process for Supplier. Supplier provides perishable produce information. Supplier can also inform users about their harvest. It consists of two types information: harvested items (harvest result ready to market), and the next harvested items. The “next harvested items” will change into harvested items after the they have been harvested and ready to market. The harvested items are the products that ready to be purchased. The application provides information of the items/products including product name, size, brix, stock, price, and discount (if available). There are two types of incoming orders processes, with and without bargaining process. A Chat feature is provided for bargaining process, if both parties agree with the price, the orders will be changed to delivery and tracking process. The application also provide feature to adjust ordered items, by adjusting the approved amount and selected items. The suppliers can see their account information including their incoming orders, pending orders, balance, delivered orders with the amount of the item, and expected payment date. This transactions history can be imported into excel file. If a supplier has their own system, a function to import the data from that application is provided.

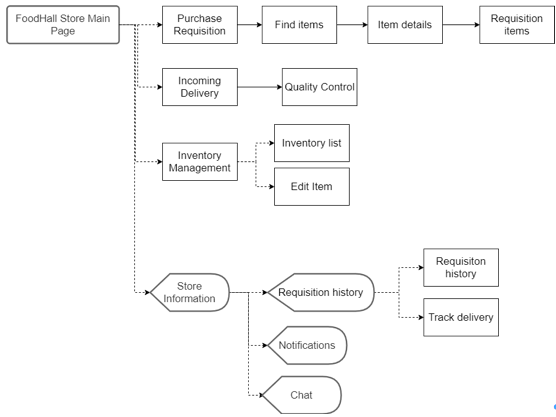

Figure 4 provides the business process for FoodHall Store. The 34 stores around Indonesia will use the application to place their perishable produce purchase requisition. The FoodhHall HO will analyze those requisitions to be approved and proceed to Purchase Order process. The incoming delivery process is managed in the quality control process. The FoodHall Stores are responsible to maintain their inventory data, for example, to edit their inventory if the items are accepted or rejected due to Quality Control result. If an item is expired, the Store has to update the inventory data of the corresponding item. All data of requisition and purchase status (including Estimated Time Arrival)together with tracking system are provided by the application in the FoodHall Store information. There is information for regular incoming time schedule as well. A notification page is provided to provide notification that illustrate there will be an incoming order from Distributed Center or Supplier.

Figure 4 FoodHall Store

The business process of FoodHall Head Office is presented in Figure 5. The FoodHall HO is responsible in placing the Purchase Order of the perishable produce from supplier. There are two types of Orders from FoodHall HO: Standing Order and Purchase Order. Standing Order is for regular and repeated order, whereas the Purchase Order is to proceed the FoodHall Stores requisitions. Store Number is used for internal requisition order to HO. The received goods will go directly to FoodHall Store or Distribution Center. The FoodHall HO can also manage promotions of the items. All the promotions are decided by FoodHall HO to be applied to all FoodHall Store. This promotion is connected by the POS system of FoodHall. All the transaction data will also be connected to the FoodHall SAP system, by applying back-end synchronization function. The FoodHall HO must be able to monitor the performance of all involved parties: Foodhall Store, Supplier, and Distribution Center. A KPI Dashboard provides all the information needed for monitoring process. This Dashboard system will apply a machine learning process to explore statistical and historical information from the SAP. The FoodHall HO can obtain real time performance of Foodhall Store, Supplier, and Distribution Center and the trends of the supply and demand of perishable produce. This information will also support the decision-making process. FoodHall HO manages the inventory and their account information: purchase history, requisition history, and track delivery.

Figure 5 FoodHall Head Office

Figure 6 presents Distribution Center business process. The Distribution Center is responsible for checking the quality of the goods delivered to the Distribution Center. The main function is to process the incoming order from Supplier or FoodHall Store after receiving goods. The orders are then transferred to Quality Control Process. The Quality Control decides whether an item is accepted or rejected. Distribution Center manages it inventory by adjusting good received and dispatching items to FoodHall Stores. Since Distribution Center is provided by a third party company, this application will be connected to their application.

Figure 6 Distribution Center

User Characteristics

Table 1 lists the groups of application users with details of their access features and rights:

| User Group/Role | Access features | Access Right |

|---|---|---|

| Administrator | User account management | Read and Write |

| Supplier | Harvest and Product information | Read and Write |

| FoodHall Store | Inventory management and Requisition | Read and Write |

| FoodHall HO | Inventory management, Order, promotion and dashboard | Read and Write |

| Distribution Center | Inventory management, Quality Control | Read and Write |

Platform

The application developed is a mobile-based application that operates in both Android and IOS operating system.

Specification

Interface Requirement Specification

The following sub section presents the interface requirement for the application to produce its services.

Hardware Interface

For inventory management, a bar code reader is needed in order to identify the incoming and out coming goods.

Software Interface

The followings are the software interface of the application:

- Supplier application

- FoodHall SAP

- Distribution Center application

- Google Maps for tracking system

APIs are used to connect those applications.

Data Specification

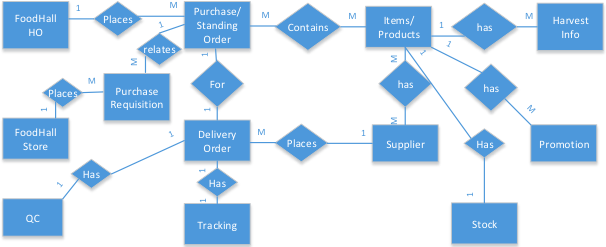

Figure 7 describes the conceptual data of the application in the form of Entity Relationship Diagram.

Figure 7 ER Diagram

As presented in Figure 7 there are 12 entities and two relationship entities in the system. The followings are the attributes for each entity:

FoodHall Store:

- Store_id

- Store_name

- Location

Purchase Requisiotin:

- PR_id

- Items

- Notes

Purchase/Standing Order:

- PO_id

- Items

- Status

- Notes

PO-Item:

- Number of item

- Type

Items:

- Item_id

- Item_name

- Item_unit

- Item_price

Harvest Info:

- Date of planting

- Date of harvest

- Number

Supplier:

- Supplier_id

- Supplier_name

- Supplier_location

Supplier-Item:

- Number of item

Promotion:

- Promotion_number

- Promotion_discount

- Promotion_notes

Delivery Order:

- DO_id

- Notes

Tracking:

- Status

- Location

- Date and Time

QC:

- DC Location

- Result

- Action

- Notes

FoodHall HO:

- HO_Id

- HO_name

Stock:

- Number of stock

Functional Specification

From the business process presented in Section 2, the followings are the main functions provided by the application:

- Authentication and Registration

- Purchase Order System

- Inventory Management

- Harvest Information

- Account Information

- Quality Control

- KPI Dashboard

- Promotion System

- Tracking Information

Non-Functional Specification

This mobile application is intended to provide services for online supply and demand process. Followings are some non-functional requirements of the application:

- Usability: All users benefit from the effectiveness and efficiency process of doing business through the utilization of the application.

- Security: The application protects all data and information from being stolen and hijacked.

- Maintainability: The application is highly responsive for data changes. Over time, more users will utilize the application and therefore, this application needs to utilize it optimally.

- Reliability: The application is reliable to work accordingly by performing the correct function at the desired level of performance.

Conclusion and Acknowledgements

Every business strives for better performance. This better performance can be viewed in comparison to existing competitors and overall process improvements to their state of operations. Improvements usually come when businesses utilise systems thinking and take a hard look at their systems. They should facilitate innovation at some acceptable level of risk. Most contemporary firms are also expected by their consumers to credibly wear green credentials.

For The Foodhall, less wastage and increased sales is the route that can satisfy these aspirations; better business performance through optimised orders, and green credentials through waste reduction. Our team worked closely with The Foodhall stakeholders to identify a solution that uses technology to connect the various ‘agents’, or elements in the produce chain system of The Foodhall. In the process, the connected system (order and tracking app) brings the additional value of assurance. When farmers and suppliers are assured of orders and payment through visibility on the orders segment of the app, the trust between the start of the produce chain and The Foodhall is increased. The gap we have addressed is the need for consolidation on a common platform. This is our Happy Digital X solution and service. Through the app, information sharing and analysis is encouraged, facilitated, and beneficial. When ordering behaviours and patterns become more of a science, we can ultimately achieve efficiency and accuracy of orders so that at point of sales, the right amount of product push enables better revenue, and also less waste as the orders are predicted, or predicated from past demands. Of course, we understand that beyond our proposal and mock up of the app, The Foodhall will still have to take further steps to carry forward development.

Our team would like to acknowledge Mr. Kiat Boon, Head of Fresh, The Foodhall, who kindly contributed his time to review our solution, and offer his suggestions for improvement. We also like to thank our course lecturers and plenary speakers for contributing greatly to our learning. We would also like to acknowledge the other teams who generously shared their presentations and learning insights, as well as learning journey. Finally thanks to our team mates who spent many hours discussing and developing our challenge project solution.

References

To gain a better sensing of the project and being continuous learners, several sources of information proved useful to our team. These articles allowed us to gain insights into the best practises of supply chain management, in particular to the farming and grocery business

- The food chain: Japanese agriculture - from farm to supermarket (https://hackerfarm.jp/2019/04/the-food-chain-japanese-agriculture-from-farm-to-supermarket/ )

- Winning the Food Fight: Best Practices for Managing Grocery Retail Supply Chains (https://www.relexsolutions.com/resources/managing-grocery-retail-supply-chains/)

- The secret to smarter fresh-food replenishment? Machine learning (https://www.mckinsey.com/industries/retail/our-insights/the-secret-to-smarter-fresh-food-replenishment-machine-learning?cid=eml-web)

- 3 Steps to a Digital Supply Chain (https://www.gartner.com/smarterwithgartner/3-steps-to-a-digital-supply-chain/)